Intumescent Fire Protection Coating

Safety by foam barriers

Steel and fire protection – a challenge which has become increasingly important over the last 30 years. In the construction of modern buildings, great store is set by an attractive architecture with exposed filigree steel profiles. Structural members such as columns, girders and framework made of steel create a fascinating combination of functionality, power and elegance. But the heat of fire puts all this at risk.

| Fire protection systems for steel | water-based |

| RENITHERM® PMA 1200 HD | water-based 1C system, interior use R15-R180, Green Product |

| RENITHERM® PMA 600 HD | water-based 1C system, interior use R15-R90, Green Product |

| Fire protection systems for steel | solvent-based |

| RENITHERM® PMS 1200 H | solvent-based 1C system, interior/exterior use R15-R120 |

| RENITHERM® PMS-R | solvent-based 1C system, interior/exterior use R15-R120 |

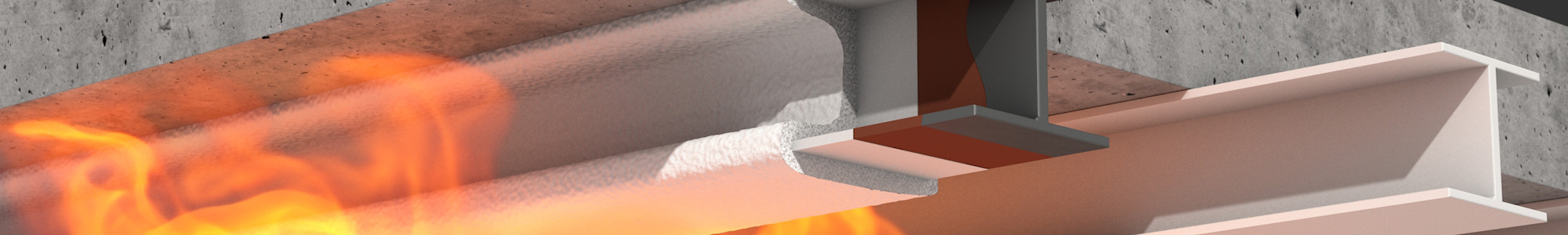

The way RENITHERM® functions is as ingenious as it is simple. The thin coating of fireproofing agents forms an insulating shell. Under the influence of fire or high temperatures, it expands, forming a dense, non-flammable foam layer of several centimetres thickness.

This reaction takes place at temperatures at which timber is not yet destroyed. Thereby, a substantial part of the heat is withdrawn, which absorbs energy from the fire.

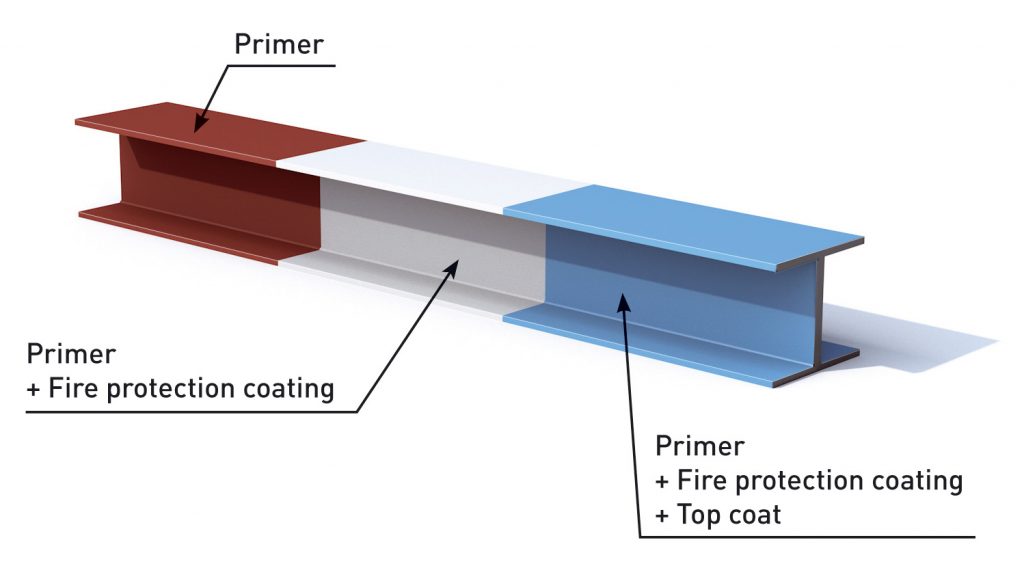

Coating set-up on Sa 2.5 blasted steel

The thin RENITHERM® coating for steel surfaces reacts under the effect of heat. An endothermic reaction of the fire protection coating causes a very thick insulating layer to form on the steel surface. This highly efficient protection postpones the time when the steel reaches its critical temperature.

These special coatings significantly help to delay the bursting of steel in the bearing structure of a building. A RENITHERM® fire protection coating provides approximately two additional hours to rescue people from the danger zone and to retain the value of the building by firefighting measures. Timber and cables bear up against the fire longer with RENITHERM® coatings.

In case of fire, RENITHERM® foams up to 30 to 50 times its original thickness and reduces the transmission of heat, greatly improving the chance to conserve the buildings.